Harbor Freight Tools 61972 Support Question

Find answers below for this question about Harbor Freight Tools 61972 - 10 in. Sliding Compound Miter Saw.Need a Harbor Freight Tools 61972 manual? We have 1 online manual for this item!

Question posted by timhightower on October 22nd, 2016

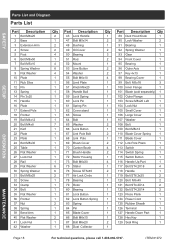

Replacement Part For Chicago 10' Miter Saw

I need to replace the chicago miter saw positive stop lock lever. It cracked on one side. This will be the yellow thumb like button on the front the round know is running through that lets you swing the saw left to right.

Current Answers

Answer #1: Posted by Odin on October 22nd, 2016 4:58 PM

Your first step should be to call the manufacturer. See the contact information here: See the contact information here--https://www.contacthelp.com/Harbor%20Freight%20Tools/customer-service. If you can't get the part from the company you may be able to obtain the part number. Then try the following: * Try an online parts source like http://www.ereplacementparts.com/ or https://www.partstore.com/ * Contact local tools dealers, who might be able to supply or maybe fix the part * Enter your part number in a search engine like Google or Yahoo * Try http://www.searchtempest.com/, which displays global listings from eBay, Craigslist, and other sourcest

Hope this is useful. Please don't forget to click the Accept This Answer button if you do accept it. My aim is to provide reliable helpful answers, not just a lot of them. See https://www.helpowl.com/profile/Odin.

Related Harbor Freight Tools 61972 Manual Pages

Similar Questions

Price For Motor On 10' Compound Slide Miter Saw. Item 61972

(Posted by maisongoodrich 2 years ago)

Harbor Freight 10” Sliding Compound Saw Handle Replacement

I purchased a Harbor Freight 10" sliding compound saw at a store sidewalk sale a number of years ago...

I purchased a Harbor Freight 10" sliding compound saw at a store sidewalk sale a number of years ago...

(Posted by Br1nkl3yrose 2 years ago)

Switch For 61972 Sliding Miter Saw

this miter saw began to malfunction with saw blade staying on without squeezing the trigger. I think...

this miter saw began to malfunction with saw blade staying on without squeezing the trigger. I think...

(Posted by Inchhighprivateeye 2 years ago)

Measurements For Connecting Bar For 61969 - 12 In. Miter Saw

61969 - Chicago Electric 12 in. Double-Bevel Sliding Compound Miter Saw.I bought this miter saw but ...

61969 - Chicago Electric 12 in. Double-Bevel Sliding Compound Miter Saw.I bought this miter saw but ...

(Posted by mathewpatterson 2 years ago)

Need 102 Outer Fllange For Chicago Electric 10” Sliding Compound Miter Saw Ite

looking for outer flange for Chicago electric 19" sliding compound miter saw item 61972

looking for outer flange for Chicago electric 19" sliding compound miter saw item 61972

(Posted by nelliethedog1 2 years ago)